Resistance spot welding is a time-tested, precise metal joining technique crucial for auto body work, offering speed, strength, and versatility. It generates heat through electrical resistance, creating strong, permanent bonds with minimal metal distortion, suitable for diverse metals and alloys of varying thicknesses. This method streamlines repair processes in collision centers, reduces finishing needs, and is preferred for auto frame and car body repairs due to its ability to withstand extreme conditions and ensure structural integrity without compromising aesthetics. It excels where adhesives struggle, making it a go-to option for precision body shop services requiring robust and permanent bonds between challenging materials.

In the realm of repairs and fabrication, choosing the right joining method is paramount. While adhesive bonding has its merits, resistance spot welding offers a robust alternative—especially in certain scenarios. This article delves into the fundamentals of resistance spot welding, highlighting its advantages for repair work. We explore specific situations where this technique excels over adhesives, providing insights to help professionals make informed decisions.

- Understanding Resistance Spot Welding: A Basic Overview

- Advantages of Using Resistance Spot Welding for Repairs

- When Adhesive Bonding Falls Short: Scenarios for Spot Welding

Understanding Resistance Spot Welding: A Basic Overview

Spot welding is a specialized metal joining technique that has been an integral part of auto body work for decades. It involves using a resistance spot welder to join two or more metal pieces together by generating heat through electrical resistance. This process creates a strong, permanent bond, making it a popular choice in various industries, including automotive, aerospace, and manufacturing.

Resistance spot welding is particularly effective for auto collision centers dealing with vehicle paint repair as it offers precise control over the weld area, ensuring minimal distortion of the metal. The technique is versatile, capable of joining different metals and alloys, and can handle a range of thicknesses, making it suitable for various auto body work applications. This method also provides consistent quality, strong bonds, and minimizes post-welding finishing requirements, thus streamlining the repair process in an auto collision center.

Advantages of Using Resistance Spot Welding for Repairs

Resistance spot welding offers several advantages that make it a preferred choice for many repairs, particularly in auto frame repair and car body repair scenarios. One of its key benefits is speed; this technique allows for quick assembly and bonding, which is crucial when dealing with damaged vehicle structures. Unlike adhesive bonding, spot welding provides a permanent and robust connection, ensuring the integrity of the car’s structural elements. This method creates a strong weld that can withstand significant forces, making it ideal for reinforcing damaged areas without compromising overall stability.

Additionally, resistance spot welding is versatile and suitable for various materials commonly used in auto detailing and car body repair. It can be applied to metals like steel and aluminum, ensuring a secure bond regardless of the specific material. This versatility, combined with its efficiency, makes spot welding an attractive option for professional mechanics seeking reliable and long-lasting repairs.

When Adhesive Bonding Falls Short: Scenarios for Spot Welding

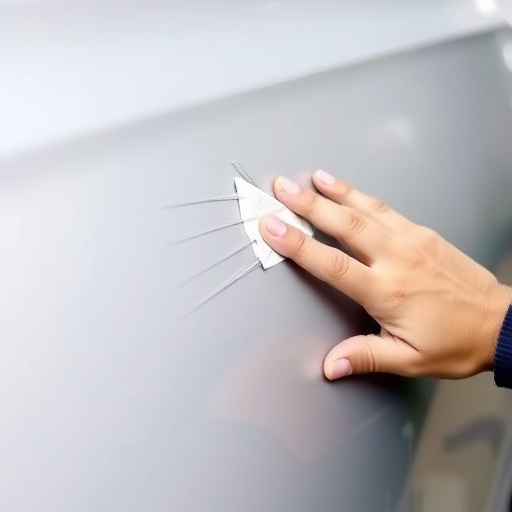

In certain scenarios, adhesive bonding simply isn’t up to the task when it comes to repairs. Adhesives can fail due to a variety of factors such as extreme temperature changes, high stress points, or exposure to corrosive substances – common issues in vehicle dent repair and other body shop services. Additionally, some materials, like metal, don’t adhere well to adhesives, making resistance spot welding the preferred choice for bonding them together.

Spot welding offers a robust and permanent solution by creating a strong metallic bond through heat and pressure, making it ideal for structural repairs in vehicle body repair. It is particularly effective when speed and strength are paramount or when specific areas of a vehicle need to be reinforced without compromising overall aesthetics, as is often the case in precision body shop services.

Resistance spot welding offers a robust and reliable solution for various repair scenarios, especially when adhesive bonding may fail due to factors like extreme conditions or material incompatibility. By understanding the advantages outlined in this article, professionals can make informed decisions, ensuring that resistance spot welding is utilized effectively to produce durable, high-quality repairs.